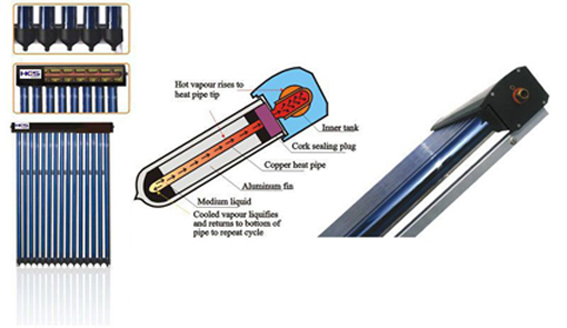

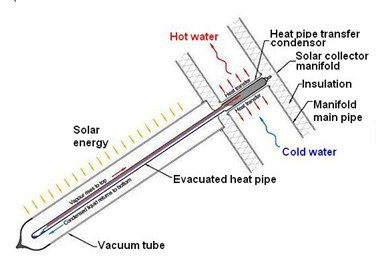

Heat pipe solar collector working theory

Basic principle:

Vacuum tube absorb solar energy and transfer to heat pipe via aluminum fin, heat pipe is heated and working liquid vaporize and rise to the top heat pipe condenser (condenser is inserted into the mainfold port inside the solar collector manifold), when the heat pipe condenser meet cold water flow inside the manifold port, the working liquid will cool down andfluidify return to the bottom of heat pipe, so once and once again repeat this process, so finally cold water(glycol) inside the manifold port will be heated.

Westech Solar Collector Specification:

|

Solar Collector Specifications

|

|

Manifold Casing Material

|

2.0mm Aluminum Alloy

|

|

Frame Material

|

2.5mm Aluminum alloy

|

|

Header Pipe Material

|

99.93% pure copper , Diameter24mm

|

|

Insulation

|

Compressed Rock Wool

|

|

Rubber Seals and Rings

|

HTV grade silicone rubber

|

|

Flat roof installation angle

|

15o -----75o

|

|

Maximum Operating Pressure

|

10bars

|

|

Optimal flow rate

|

0.1L/min/tube

|

|

Performance Data

|

See EN12975 testing and SRCC OG-100 testing

|

|

Model

|

Vacuum tuber

|

Daily Output

|

Absorber

|

Size (mm)

|

Quantity( sets)

|

|

(L/Day/60°C)

|

Area( M2)

|

L

|

W

|

H

|

20" t

|

40"t

|

|

HCM12-58/1800

|

Ø 58x1800*12Pcs

|

85 ----120

|

1.68

|

1970

|

1015

|

180

|

130

|

270

|

|

HCM15-58/1800

|

Ø 58x1800*15Pcs

|

105 ----150

|

2.1

|

1970

|

1240

|

180

|

110

|

230

|

|

HCM20-58/1800

|

Ø 58x1800*20Pcs

|

140 ----200

|

2.8

|

1970

|

1615

|

180

|

85

|

170

|

|

HCM30-58/1800

|

Ø 58x1800*30Pcs

|

210 --300

|

4.2

|

1970

|

2365

|

180

|

55

|

115

|